Do You Want to Handle Your Pallets Safety in The Warehouse?

Pallets are now so widespread in warehouses that they are nearly invisible. However, without pallets, global trade would function similarly to a car without tyres. You require material handling pallets for this reason.

The primary interface of a unit load is a pallet. A pallet serves as a unit load’s main interface. They defend merchandise as it moves through the supply chain, absorb fork truck impact, support weight, and deflect pressure.

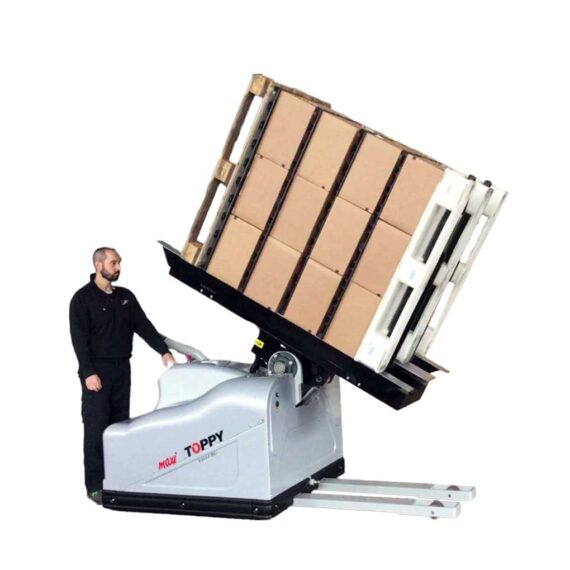

Pallets are the most frequently utilised piece of equipment in material handling facilities, making safe handling of them crucial. A palettenwender (English Meaning = pallet turner or pallet inverter) is a great place to start if your warehouse has a problem with safety awareness and you want to make improvements.

The following are three varieties of pallet inverters:

- Manual

- Semi-automatic

- Automatic.

Pallets are the first line of defence to ensure that goods arrive at their destination unharmed and in the same condition as when they were sent. Therefore, you must:

- Choose the best quality pallets available

- A higher product volume per shipment

- Reduce the products number lost due to damages/contamination

- Prevent any worker injury

- Reduce expenses like fuel costs.

Steps for pallet safety

Never raising anyone using pallets is the first and most obvious rule. It is best to avoid standing on pallets at all costs. Standing on a pallet can result in a broken slat or a foot caught in a trap since pallets are made to support consignments that are uniformly distributed throughout their surface.

Pallets can occasionally be stacked closely together to the point that it is difficult to access their contents without standing on the pallets. It is preferable in these circumstances to relocate the pallets so you may get the things you require.

Speaking of pallet storage, keep stacks under four feet high when piling pallets on top of one another. Without the use of handling tools, all workers in a warehouse should be able to take out a pallet from a stack with ease.

To further lower the chance of an accident, enlist the aid of a second person whenever you can when removing a stacked pallet. Before attempting to remove the pallet, be sure it is not caught on the pallet below or anything close.

Holding the pallet as vertically and closely to your body as you can while carrying it is the correct approach. This will assist you in keeping your centre of gravity constant so you don’t fall while carrying a pallet.

Hand and foot injuries make up the majority of injuries caused by pallets in warehouses. To completely remove the risk of injury when handling pallets, all you need to do is put on gloves and protective footwear.

Clear any path or work area of any impediments. Keep all areas of the warehouse clear of debris because when moving a pallet or using equipment, awareness of potential impediments is diminished.

Finally, never try to use any damaged pallets for work. Those pallets that are broken must either be recycled or discarded for avoiding any injury to your personnel and materials.